Water operations face increasing pressure to deliver more quality water with fewer resources, but must cope with many challenges, including higher costs, environmental stress, increasing regulations, and a growing population. In addition, many operators have aging and disparate systems that cannot deliver the efficiency needed for maximum profitability and future growth

Water operations face increasing pressure to deliver more quality water with fewer resources, but must cope with many challenges, including higher costs, environmental stress, increasing regulations, and a growing population. In addition, many operators have aging and disparate systems that cannot deliver the efficiency needed for maximum profitability and future growth

Automation is well established in the water treatment industry. However, better instrumentation would help alleviate concerns about unattended operation.

Gururaj Engineers supplies technologies for water and wastewater applications.

Our focused areas of expertise includes

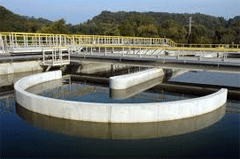

Waste water treatment

Petroleum refineries and petrochemical plants all generate oily wastewater to some extent, and the oils contained in those wastewaters can vary widely. Removal of oils from wastewater is normally one of the first steps in the treatment of wastewater and arguably, the most important treatment step.

Cooling Tower water treatment

The largest volume of water required by an electric generator typically will be used in the cooling tower. Air cooled condensers are being applied in the industry, however their use reduces the efficiency of the power plant. Hybrid (both wet and air cooled) are also being applied and will also require water treatment in most cases. A side stream may also be treated in order to conserve water by increasing the cycles of concentration in the cooling tower through the reduction of suspended and dissolved solids, silica and other constituents based upon the needs of our customer.

Raw Water Pretreatment

Surface water, well water or reclaimed water can contain suspended solids, colloidal matter, organics, hardness, silica, iron, manganese and other contaminants. That’s why it’s so important to choose the proper water pretreatment system for your process. We at M/s Gururaj Engineers can help you design the most efficient, reliable and cost-effective pretreatment system.